GRP Water Tanks

Setting the standard for cleanliness, hygiene, and leak-proof excellence. Our Sectional GRP Water Tanks offer easy customization for tailored designs.

Ajman, UAE

+971 56 945 7866

support@thewatertankcompany.com

Setting the standard for cleanliness, hygiene, and leak-proof excellence. Our Sectional GRP Water Tanks offer easy customization for tailored designs.

GRP (Glass Reinforced Plastic) water tanks are containers used for storing water. They're made from a combination of high-quality fiberglass and resin, resulting in a durable and corrosion-resistant structure suitable for various environments. Here are some key points about GRP water tank products:

Material Composition: GRP tanks are composed of fiberglass reinforced with plastic resin. This combination provides strength and durability, making the tanks suitable for long-term water storage.

Corrosion Resistance: One of the primary advantages of GRP tanks is their resistance to corrosion, even when exposed to harsh chemicals or varying weather conditions. This makes them ideal for both indoor and outdoor use.

Lightweight and Easy to Install: GRP tanks are relatively lightweight compared to traditional materials like steel, making them easier to transport and install. They can be assembled on-site, reducing transportation costs.

Insulation Properties: GRP tanks can be manufactured with insulation properties to help maintain the water temperature, reducing the need for additional heating or cooling systems in certain situations.

Hygienic and Safe: The smooth internal surface of GRP tanks prevents the growth of algae, bacteria, or other contaminants, ensuring stored water remains clean and safe for use.

Environmental Considerations: GRP materials are environmental friendly and recyclable, adding to their appeal for those concerned about sustainability.

When considering a GRP water tank, it's important to verify the quality standards, certifications, and the manufacturer's reputation to ensure a reliable and durable product that meets specific requirements. Regular inspection and maintenance are also recommended to prolong the tank's lifespan and ensure optimal performance.

| Manufacturing Process | Hot pressed SMC compression moduling. |

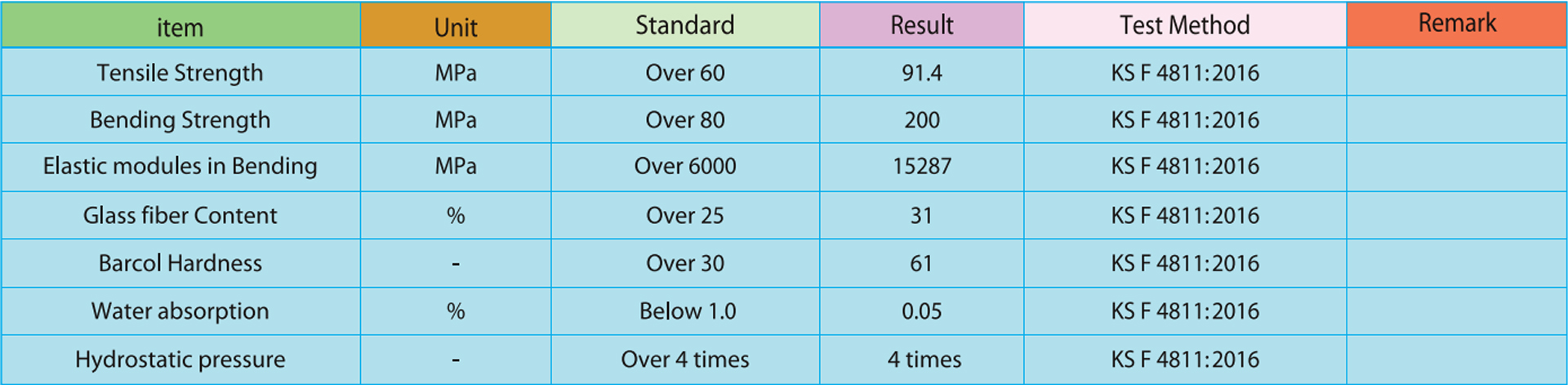

| Hydrostatic pressure | Water pressure reinforcement 4 times standard Transformation rate in filled with water : less than 1% form water tank heigh. |

| Wind force | Less than 60m/sec |

| Earthquake force | Stable and safe till magnitude 5.0 (over magnitude 5.0, it needs additional reinforcement) |

| Snow load | 60Kg/m², snow fall less than 30cm |

| Illumination rate | Less than 0.1% |

| Out-fit force | No leakage under condition of vertical 100Kg after install of 100A fitting with 70mm span supprot |

| Water temperature | Usable temperature : less than 30°C / limited temperature : max 70°C |

| Water quality | Tap water, well water : chlorine below 50mg/L Seawater : application externally reinforced water tank (max 3m height) |

Copyright 2023 Industry. All rights Reserved

Home | About Us | Privacy Policy